Mechanical Vapor Recompression (MVRE)

Sanskriti Enviro Private Limited is a consolidated consultancy and Water and Waste Water Management Company.

Mechanical Vapor Recompression (MVRE)

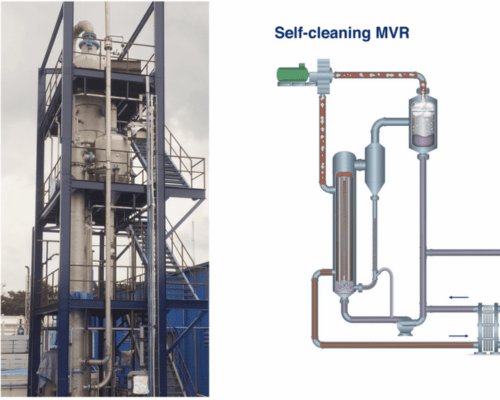

Mechanical Vapor Recompression (MVR / MVRE) is an advanced, energy-efficient evaporation technology used for treating high TDS and high COD industrial wastewater. At Sanskriti Enviro, we design and supply state-of-the-art MVR systems that significantly reduce steam consumption and operating costs while maximizing water recovery.

MVR technology is widely adopted in Zero Liquid Discharge (ZLD) projects where sustainability, energy efficiency, and regulatory compliance are critical.

What is Mechanical Vapor Recompression (MVR / MVRE)?

Mechanical Vapor Recompression is a process in which the vapor generated during evaporation is mechanically compressed using a blower or compressor. The compressed vapor is then reused as a heating medium within the same system.

This recycling of vapor energy makes MVR systems far more energy-efficient compared to conventional Multi Effect Evaporators (MEE), resulting in lower operational costs and reduced carbon footprint.

Our MVR / MVRE Plant Solutions

Sanskriti Enviro offers customized Mechanical Vapor Recompression systems designed as per effluent characteristics and plant capacity, including:

Forced Circulation MVR Evaporators

Falling Film MVR Systems

Integrated MVR with ATFD / Crystallizer

ZLD-Based Evaporation & Concentration Systems

Fully Automated PLC / SCADA Controlled Plants

Our solutions ensure stable performance even for complex and challenging wastewater streams.

Contact us

MVR Treatment Process

The Mechanical Vapor Recompression process typically includes the following steps:

1. Feed Pre-Treatment

Effluent from ETP/RO systems is pre-treated to minimize scaling and fouling inside the evaporator.

2. Evaporation

The wastewater is heated and partially evaporated under controlled conditions.

3. Vapor Compression

The generated vapor is compressed using a mechanical compressor, increasing its temperature and pressure.

4. Heat Reuse

The compressed vapor is reused as a heat source for further evaporation, drastically reducing energy consumption.

5. Condensate & Concentrate Handling

High-quality condensate is recovered for reuse, while concentrated reject is sent to ATFD or crystallization systems.

Key Features of Our MVR / MVRE Plants

Extremely low energy and steam consumption

High recovery of reusable water

Ideal for continuous and large-capacity operations

Compact design with minimal utility requirement

Robust construction with corrosion-resistant materials

Easy integration with ETP, STP, RO, and ZLD systems

Applications

Our Mechanical Vapor Recompression systems are suitable for:

Pharmaceutical & Bulk Drug Industries

Chemical & Specialty Chemical Plants

Textile & Dyeing Units

Distilleries & Fermentation Industries

Food & Beverage Processing Units

Zero Liquid Discharge (ZLD) Projects

Benefits of MVR / MVRE Installation

Significant reduction in operating and energy costs

Maximum water recovery and reuse

Lower environmental impact and carbon footprint

Reduced dependency on fresh steam

Long-term cost savings for industries

Why Choose Sanskriti Enviro?

Expertise in advanced evaporation & ZLD technologies

Customized system design based on wastewater analysis

Turnkey execution from engineering to commissioning

Energy-efficient and future-ready solutions

Strong after-sales service and AMC support

Regulatory Compliance

Our MVR / MVRE Plants are designed to comply with CPCB, SPCB, and other statutory environmental regulations, helping industries achieve ZLD targets with confidence.

Contact Us

Looking for an energy-efficient Mechanical Vapor Recompression (MVR / MVRE) solution for your industry?

Contact Sanskriti Enviro today to get a customized MVR system designed for efficiency, compliance, and sustainability.

customer review

Our customers trust Sanskriti Enviro for reliable, efficient, and compliant environmental solutions. Their valuable feedback reflects our commitment to quality, timely execution, and long-term support. We take pride in building strong relationships by delivering sustainable solutions that exceed expectations.

Designation

We (a B Braun group company) has engaged with Sanskriti Enviro Pvt. Ltd since 2020. I would like to say that team of Sanskriti is highly qualified in terms of consulting the Environmental aspects specially in waste water treatment and optimization sigment. Highly recommended.

Designation

I wouldn’t hesitate to recommend Sanskriti Enviro Pvt Ltd for AMC purposes. Their team of experts have assisted us with everything from operating our Effluent Treatment Plant & Sewage Treatment Plant along with Industrial RO. they are perfect in Water & Waste Water Solutions.

Designation

Sanskriti Enviro O&M services are so charming and we are pleased to use for our MEE Plant.

Designation

We were facing problems with ETP, UF and RO plants and we consulted Sanskriti Enviro Pvt Ltd for their AMC services. Till then we never face any hassle of our Water plants.